| mass | |

|---|---|

| outer diameter | |

| inner diameter | |

| length of rectangular cut out | |

| width of rectangular cut out | |

| thickness | |

| density of steel, 0.285 \(\frac{\mathrm{lbs}}{\mathrm{in}^3} \) | |

| radius of corners of rectangular cut out |

During the COVID-19 pandemic, home fitness equipment was soldout across the US. Rogue fitness, eliteFTS, Sorinex, Capps Barbell, York Barbell, and Titan Fitness (to name the most popular US companies) have been largely sold out of plates, racks, and barbells since March 2020. Lead times, as of September 2020, are now at least 6 to 8 weeks if companies are taking orders at all. At a time when gyms across the country and gym equipment manufacturing facilities have been forced to close, home gym equipment has never been in higher demand or shorter supply. At the request of my father and a few friends, I have come up with some solutions to the problem of racks, benches, and weights.

In 2019, rusty old weight plates were available in my area for $0.50 to $1.00 per pound. Quality, new, steel plates were typically $1.50 to $2.50 per pound. During the social-distancing lockdown, rusty plates on craigslist were selling for $5.00 per pound if they were available at all. New plates were sold out completely.

Unfortunately for my friend, he was becoming stronger and needed a few extra plates but he did not want to spend $5 per pound. Fortunately, steel supply companies often have plasma CNC tables and will cut CAD designs out of 1/4" to 6" steel plate for surprisingly cheap. I drew up some plate designs and we paid $1.11 per pound, probably less than we would have paid for new plates in the pre-COVID era. That being said, the price of steel is a commodity like gasoline. It is generally priced per pound (in the US) and that price fluctuates by day and the quantity purchased. Also like gasoline, prices are wildly inconsistent throughout the country. We undoubtedly paid an unusually low price per lb for these since steel prices have been volatile in the wake of COVID-19.

In general, barbell plates are not manufactured to the stringent quality control standards. As some gym owners and bloggers have pointed out, most cast-steel barbell plates do not weigh what their face-value indicates. They are often off by 5-10% so a face-value 45 can be anywhere from 40 to 50 lbs though most are within 2 lbs of their face-value. We bought (8) of the 35 lb plates here for $311 and weighed them all with this scale. They all weighed between 35.5 and 35.8 lbs. They are not perfect but they are at least as accurate as cast iron plates. I have not purchased any of the other individual plates so feel free to check my work before you take them to a steel supply place.

When the plates are picked up from the fabrication shop, you will need to spend some time with an angle grinder and flap disc to round over all the sharp edges. Clean the plates with acetone or paint thinner and then spray paint to the color of your choice.

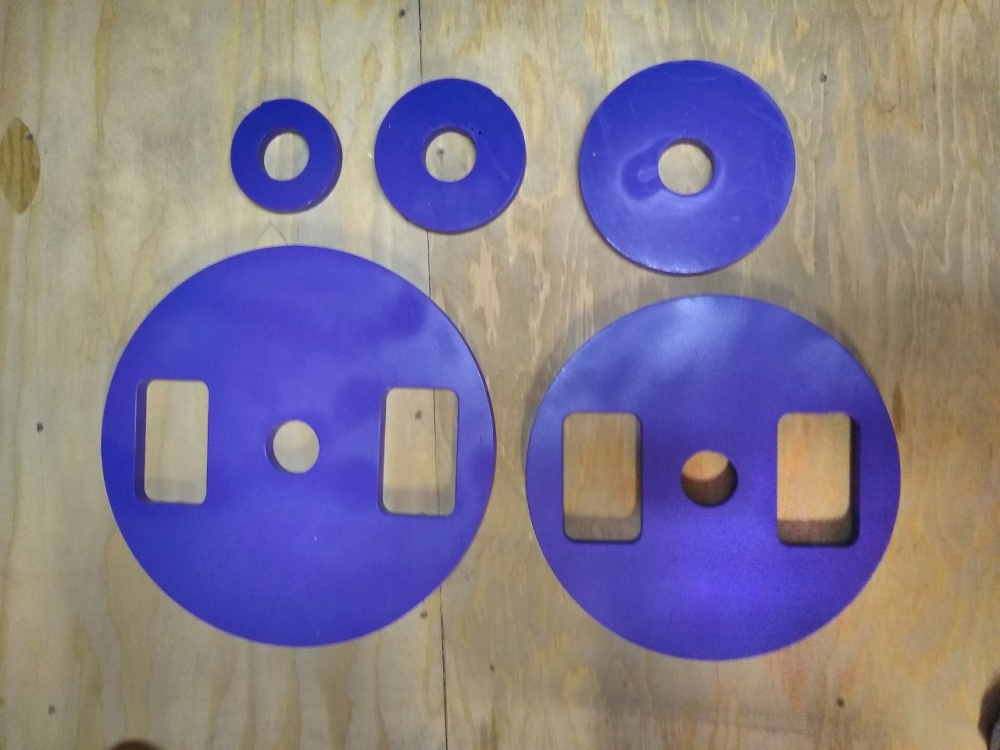

[Caption] Plasma CNC cut weight plates from the 35 lb dxf file below. Each plate weighted between 35.2 and 35.8 lbs which is within the manufacturing tolerances of most commercially available plates.

After I had cut these 35 lb plates cut for my friend, my father asked for help with his home gym. He lives across the country and needed a complete weight set. I sent a CAD file containing 245 lbs of plates to a steel supplier near my father. He lives in CA, a high tax state, so this cost about $2.50/lb ($614.30 including tax and all fees). It is important to shop around. I called about 6 steel suppliers near my father and received estimates from $614 to $8,900 (not a typo). All but one quote was over $1,500 which would obviously have been cost prohibitive at $6-$37 per lb.

[Caption] Plasma CNC cut weight plates from the 245 lb set dxf file below. [Top row] 2.5 lb, 5 lb, and 10 lb. [Bottom row] 35 lb and 25 lb. Using the same fish scale, my father found the plates weigh 2.6 lbs, 5.1 lbs, 10.2 lbs, 25.6 lbs, and 35.5 lbs.

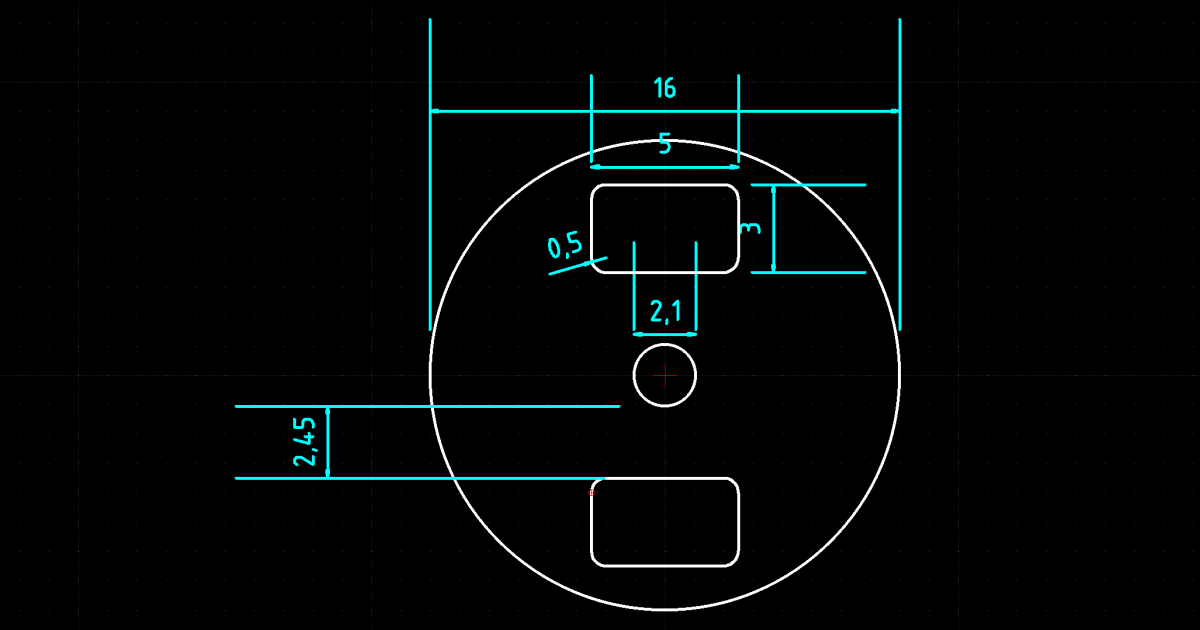

Standard full sized plates are 17.72"-17.75" in diameter depending on the resource. The CAD drawing of the 45 lb plate below is 17.75". The plates in the other CAD files are smaller. On Olympic plates, the hole is often listed as 2" but I found 2.1" made the plates easier to slide onto the bar. The error on a plasma cutter is large enough that an extra 1/10 of an inch allows the plates to reliably slide onto the barbell sleeves.

Feel free to take these to your local steel distributor or fabrication shop. They are licensed under the Creative Commons so they are free for you to use for non-commercial applications.

45 lb plate, cut from 3/4" steel plate

35 lb plate, cut from 3/4" steel plate

25 lb plate, cut from 3/4" steel plate

10 lb plate, cut from 3/8" steel plate

5 lb plate, cut from 1/4" steel plate

2.5 lb plate, cut from 1/4" steel plate

Complete 245 lb plate set, cut from 3/4" steel plate

During the pandemic, I needed a new squat rack at a friend's house. I wanted something versatile and it does not get more versatile than a yoke. The Rogue Y2 yoke can do almost anything a squat rack can do plus a variety of yoke carries. It is also more portable than a full power rack or a bolt-together squat stand. However, the Rogue Y2 is $535, the safety arms are another $135, and the shipping is at least $100. The total purchase is at least $750 and during the pandemic of 2020, it is not available even if you want to spend the money. The solution is obviously to build one.

[Caption] Rack set-up for bench pressing. Bench not homemade.

I modified the overall dimensions slightly so the pieces would fit in my Honda Civic. I also opted to use hitch pins for the safeties and J-hooks to make the fabrication significantly less challenging. You can buy hitch pins (and every other imaginable piece of hardware) from McMaster Carr. I used 1/2" x 4" loop-grip quick-release pins for this project.

When set-up as a rack and not as a yoke, the device is more stable if the uprights are held in position in the crossmember with set screws in addition to the hitch pins. My design uses 1" x 1/2" x 13 tpi set screws, also from McMaster Carr. The set screws are not necessary for any safety reason but having them reduces rattling.

[Caption] Plans for modified yoke rack, relative dimensions between different parts not shown to scale. CAD files for all parts available as separate downloads below. Download drawing as pdf.

I have deliberately not drawn the exact location of the holes on the J-hooks, crossmember, or safeties. You will have more luck positioning that hole by placing a mark on the piece while it is held against the uprights than you will by measuring. If you have access to a machine shop, you can place the hole accurately enough by measuring. However, I do not have a machine shop and most of my readers do not either. If the hole is not perfect, you can always widen it out with a die grinder.

As with most of my fabrication projects, this was welded with a DC stick welder using primarily 6013 rods of 3/32 or 1/8" diameter and electrode negative polarity. The crossmember is thick enough material that 7018 rods provided a cleaner weld without the risk of burning a hole through it.

This an incomplete picture of the cost because the J-hooks, safeties, and the feet at the bottom of the uprights were built out of scraps I had in my workshop. The paint was also not included but it took about 2 or 3 cans of flat black spray paint to cover everything. That said, here are my accounting records from the project which I believe cover 90% of the real costs.

2020-06-25 Steel Supply - 2x3 steel YOKERACK1 ............................................. 75.00

2020-07-22 Tractor Supply - drill bit for YOKERACK1 ....................................... 21.64

2020-07-23 McMasterCarr - hitch pins for YOKERACK1 ........................................ 60.60

2020-07-23 Lowes - misc pipe and supplies YOKERACK1 ....................................... 46.98

2020-08-06 Steel Supply LP - 1.5" dia pipe for YOKERACK1 .................................. 30.95

2020-08-09 Lowes return misc pipe for YOKERACK1 ........................................... -36.35

2020-08-11 Texas Iron and Metal - supplies for YOKERACK1 .................................. 78.70

2020-08-15 McMaster-Carr - set screws YOKERACK1 ........................................... 16.70

Total ................................................................................. 294.22

This device took me about 15 hours to build but I have small inexpensive tools and inefficient skills as a fabricator. I think drilling the 108 holes in this project took me at least 3 hours. An experienced fabricator in a well-equiped shop could likely do this job in less than 5 hours.

I built the first one of these before COVID because I have an outdoor squat rack. During COVID, I built two more (and counting) for friends.

Since my weight equipment is outside so there is no reason to invest in a pad which the weather will destroy. This bench was built out of 2" 11 gauge tubing welded with 3/32 6013 rods. The pressure-treated 2x12 top is attached with 1/4"x3" lag screws which come up from the underside.

[Caption] Plan for skeleton bench. Download plan as pdf.

The most inexpensive benches available are about $100 and those are far less sturdy. This bench is most comparable to the Starting Strength bench from Texas Strength Systems which retails for $240. All in this bench costs about $30 to build if you buy seconds from the steel yard and spend an extra 20 minutes grinding the rust off. It is the least expensive, least time consuming project on this page. You could argue that the Starting Strength bench is nicer but does that make it better for benching? Does a varnished solid oak top make a stronger bencher than a pressure treated 2x12? The answer is obviously no.

In designing these pieces of equipment, I was optimizing for cost. What is the least amount of money I can spend to obtain products which fulfill all the functional requirements? This bench is the furthest from a commercial looking product because commercial benches are so infected with unnecessary, expensive features.